Specalizing in thermal processing equipment and support systems, DMC Engineering is your one stop solution to all of your equipment and processing needs. Based in Wichita Kansas and servicing all of north america with furnace support, equipment installs, relocations, removals, on site rebuilds, and repairs.

Whether you're looking to break ground on a new site or upgrading existing eqiupment, DMC Engineering is here to help.

Equipment Installs and Relocations

From A to Z

Furnace and support equipment installs and relocations inclufing but not limited to:

Vaccuum and Autoclave

Integral Quench Furnaces

(Endo) RX Generators

Temper Furnaces and Box Furnaces

Water cooling towers and pump stations

Pit furnaces and Nitriders

Blasting equipment and Air compressors

Material handeling and overhead cranes

Automation control stations

And much more!

Maintenance and Repairs

Keep it running!

DMC Engineering is known for quick repairs to correct problems with the equipment with use of proper troubleshooting techniques and OEM new part replacements.

"Bandaid" repairs often fail and lead to more equipment down time and additional costly repairs, our mission is to keep your equipment running properly as intended by the manufacturer.

Preventive Maintenance and Safety Inspections

Fix it before its a problem

We offer a wide range of equipment inspections and evaluations as well as preventative maintenance services. Often PM tasks as outlined by the OEM get overlooked, causing costly downtime for repairs which could have been avoided or scheduled. Regular routine preventative maintenance will prolong the life of duty heavy parts of the equipment and allow for a window of scheduled downtime to preform replacements and repairs.

Annual safety inspections are recommended to verify the operational and failsafe safeties are functioning to prevent fatal injuries or costly equipment repairs.

Header Piping and Support

Clean and simple

There is no piping job too large for DMC Engineering. We utilize CAD drawings to find the cleanest pipe routing and utilization of supports. Offering standard service for installing sch40 steel grooved headers and sch40 steel welded connections creates a clean look, simple repairs if needed, and some ability to relocate equipment more easily.

We offer sch40 pvc up to sch80 stainless, copper pipe soldered or braised, and limited applications of PEX tubing, as well as steel pipe threaded connections up to 2".

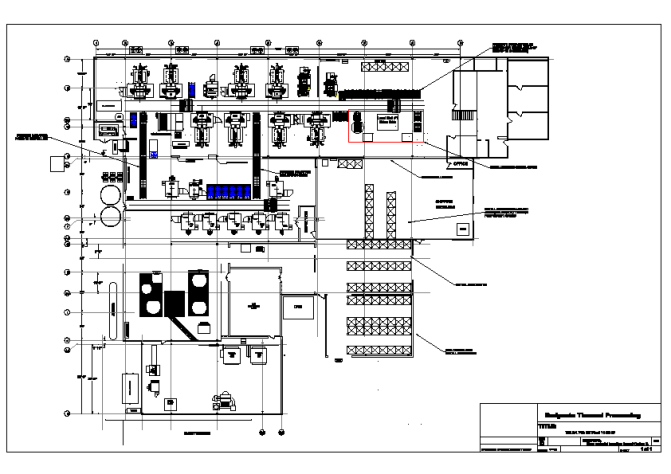

AutoCAD Drafting

2D building and Equipment layouts

We offer CAD drawings for projects or as a general layout for equipment. We often use this service to set up equipment into the site location as well as placement of support equipment and infrastructure such as electrical mains and piping.

Upon request, we can send the dwg, plt, or a PDF of the drawing for easy viewing on any device.

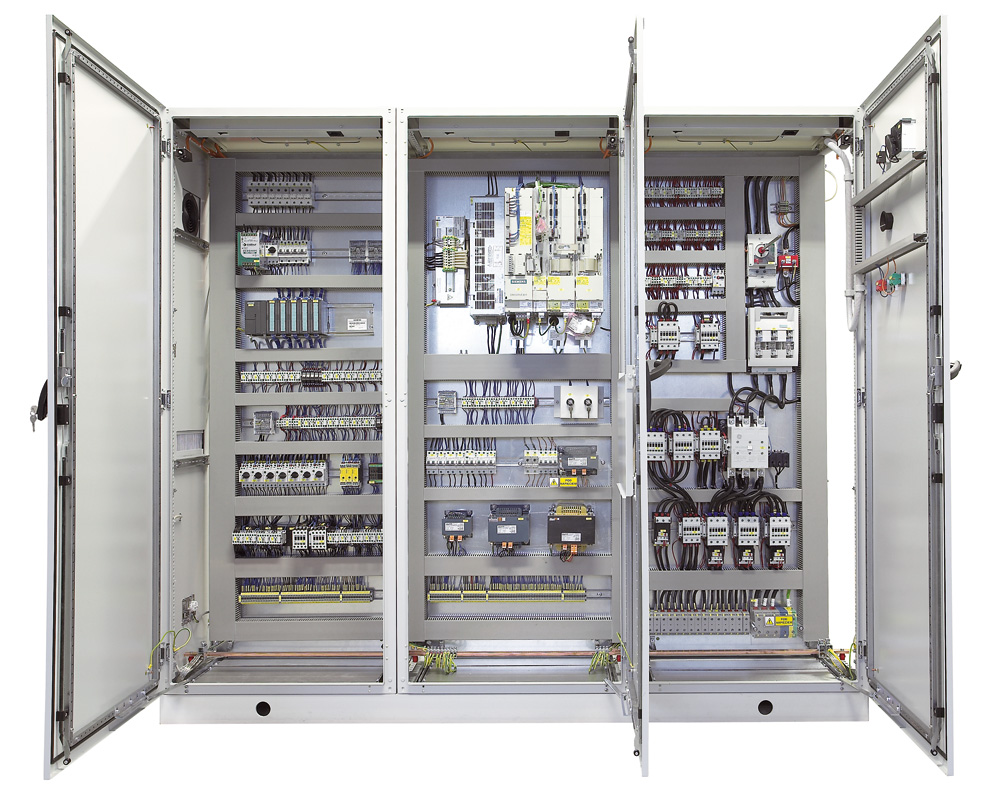

Control Cabinent Reapirs

New or Rebuilt

DMC Engineering can rebuild a control cabinent from exitsing, updating internals to new or simply rewiring existing back to the OEM schmatics.

We also offer New built cabinents and or automated controls based on the equipment capabilities.

Project Management

From Start to Finish

DMC Engineering offers project management services to assist with any of your project needs with experienced engineers in every phase of project management of multi-million dollar project budgets.

We strive to get you the best return for your investment while keeping the project on track.

Quality control and Employee Evaluations

Ensure the gears run smooth

DMC Engineering offers assistance in evaluations and solutions to various quality issues related to the equipment. Our team of engineers can provide solutions to maintain your process and ensure the quality standards are met.

DMC Engineering also offers employee evaluations based on the needs of the company and includes but not limited to operators, maintenance, and management personnel.